Published On May 28, 2024

#kamadogrill #grill #ceramic #grilling

This video delves into the fascinating world of kamado grill ceramic shell production, unveiling the meticulous artistry behind these coveted cooking vessels. We'll embark on a journey from the raw clay to the finished product, witnessing the transformation of humble earth into a heat-resistant masterpiece. The video shows the step "The Art of Disguise: Surface Treatment" among the follow steps.

The Birth of Form: Shaping the Hemispheres

Our odyssey begins with high-quality ceramic clay, meticulously chosen for its optimal properties. This clay is expertly prepared, achieving the perfect balance of moisture content and consistency. Skilled artisans then employ a specialized molding technique to create the two crucial components of the kamado shell – the hemispheres.

These molds, often crafted from wood or plaster, precisely define the shape and dimensions of the hemispheres. The clay is then carefully pressed or formed within the molds, ensuring an even distribution and eliminating air pockets that could compromise the final product's integrity.

The Crucial Union: Joining the Hemispheres

Once extracted from their molds, the two hemispheres stand ready for the next critical step – their permanent union. This process requires exceptional skill and attention to detail, as a flawless seal is paramount.

The artisans utilize a specialized clay slurry, often referred to as "slip," to meticulously join the two halves. This slip acts as a powerful adhesive, ensuring a strong and seamless connection. The resulting seam is then meticulously smoothed and sculpted, eliminating any unevenness that could affect the aesthetics or functionality of the finished shell.

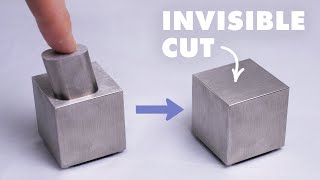

The Art of Disguise: Surface Treatment

With the hemispheres securely joined, the focus shifts to surface preparation. This stage plays a vital role in both the visual appeal and performance of the kamado. Highly skilled artisans meticulously smooth and refine the exterior surface, eliminating any imperfections or inconsistencies.

Special tools and techniques, honed through years of experience, come into play here. The goal is to achieve a flawless, uniform finish that not only enhances the kamado's visual appeal but also optimizes its heat retention capabilities. A smooth surface minimizes air pockets that could trap heat and potentially lead to uneven cooking temperatures.