Published On Jul 25, 2019

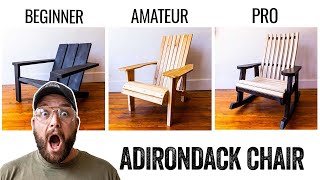

Learn how to build a modern Adirondack or outdoor chair for your patio and add modern outdoor seating to your backyard! Thanks to Bernzomatic for sponsoring this video, check out the TS8000 torch http://bit.ly/2ycz1ZE & MAP gas http://bit.ly/2Y9MYHm I used on this project! #sponsored

I have plans available for this project! (Plans coming soon, subscribe to be notified when they're live) : http://bit.ly/craftednewsletter

💰 BECOME A YOUTUBE MEMBER! / @craftedworkshop

📦 Materials Used On The Adirondack Chair (affiliate):

🔹 Rockler Zip Driver Screws : https://www.rockler.com/robertson-squ...

Thermally Modified Ash : http://bit.ly/ashevillehardware

CA Glue and Activator : https://amzn.to/30xmTP3

Brad Nails : https://amzn.to/30D77lV

Wood Glue : https://amzn.to/32LKFc5

1 ¼” Pocket Hole Screws : https://amzn.to/2LGo6Qu

10’ of ¾” Copper Pipe : https://amzn.to/30ZdL6a

4 Copper Elbows : https://amzn.to/2LI5Y8U

2 Copper End Caps : https://amzn.to/2LFEL72

🛠 Tools Used On The Outfeed Table (affiliate):

🔥 TS8000 http://bit.ly/2ycz1ZE

🔥 MAP gas http://bit.ly/2Y9MYHm

🔸 Powermatic 209HH Planer : http://bit.ly/209HH

🔸 Powermatic PJ-882HH Jointer : http://bit.ly/PJ882HH

🔸 Powermatic PM1500 Bandsaw : http://bit.ly/PM1500

🔹 Rockler Countersink Bit Set : https://amzn.to/2XGRfNd

🔹 Rockler Plug Cutter : https://amzn.to/2SGli6B

🔺 Infinity Tools Super General Saw Blade : http://bit.ly/supergeneralblade

Soldering Kit : https://amzn.to/2JRqsdh

Table Saw : https://amzn.to/2WrrNMm

Push Stick : https://amzn.to/2XIvgFq

Miter Saw : https://amzn.to/2TeGdgO

Speed Square : https://amzn.to/2XMF5CE

Magnetic Screw Holder (for my impact driver) : https://amzn.to/2xGYPwD

Cordless Drill : https://amzn.to/2wOFM2S

Pocket Hole Jig : https://amzn.to/2UWT0oi

Sander : https://amzn.to/2oHOmg7

Brad Nailer : https://amzn.to/30s8Fij

Japanese Pull Saw : https://amzn.to/2S9Zdgu

Block Plane : https://amzn.to/2V2D7h1

👕 Get your Build It Yourself merch! http://bit.ly/BuildItYourselfMerch

📹 SUBSCRIBE : https://goo.gl/V5gcNJ

📲 FOLLOW CRAFTED WORKSHOP!

INSTAGRAM: / craftedworkshop

FACEBOOK: / craftedworkshop

TWITTER: / craftedworkshop

PINTEREST: / craftedworkshop

Adirondack Chair Build Process:

I broke the Ash boards down into rough lengths at the miter saw and bandsaw. Next, I started working on the metal framework. I cut the 3/4” copper tubing pieces to length.

Next, I applied flux to the end of the tubing. To solder copper, you want to heat up the joint until the flux melts and then basically wipe the solder across the tubing until it melts and flows into the joint.

After finishing soldering, I could get back to working on the wooden portion of the chair. I started by ripping the arms and legs to final width at the table saw. I then cut the boards to length using my crosscut table.

Next, I could get to work on the joinery for the chair. I went with pocket holes.

The next pieces to work on were the back legs, which have a parallel angle of 20 degrees cut on each end, and I made these cuts over at the miter saw.

Next, I marked the location of the back leg on the front and back sides of the front leg.

After pre-drilling the holes through the front leg, I clamped the back leg in place using my t-track table and drove the screws.

I could mark out where I needed to cut a flat spot on the back legs. I could then cut to my line using the jigsaw, and I cleaned up the cut with my low angle block plane. With that, the main structure of the chair was assembled, so I could attach the copper base.

Next, I could get to work on the back panel. This is a simple assembly of four boards connected with two perpendicular cross supports at the top and bottom of the panels.

Next, I needed to get the back panel attached to the back legs. I lifted the panel into place and added the screws.

With the back panel installed, I could work on attaching the last parts of the chair, the seat. I started by adding the front seat slat. After clamping the board in place, I drove in the pocket screws.

Next, I could get the copper base removed for finishing. I used a file to remove any excess solder around the joints. I used a self-etching primer and then sprayed on a few coats of flat black paint.

I wanted to plug all of the screw holes using a plug cutter. After cutting the plugs, I popped them out with a flathead screwdriver and added the plugs to the holes with wood glue. I trimmed them flush with my Japanese pull saw.

With that, all that was left was sanding. I sanded the chair up to 180 grit, making sure to break all of the edges. I also hand sanded between all of the slats.

And with that, all that was left to do was reattach the metal base.