Published On Nov 9, 2017

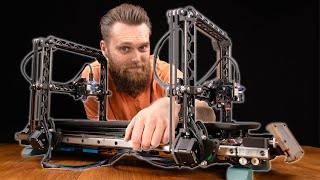

Building a benchtop cnc from 8020 extruded aluminium, and some salvaged parts. This one is stepper motor driven.

In this part I make the controlbox, wire up everything and do some test cutting at the end.

Part 1: • Building a Benchtop CNC -Part 1 - Y-Axis

Part 2: • Building a Benchtop CNC -Part 2 - Z-Axis

Part 3: • Building a Benchtop CNC -Part 3 - X-Axis

Business enquiry please email: [email protected]

Business enquiry please email: [email protected]

Some tools I use (Affiliate Links)

Any purchases supports my channel and content creation. Thanks

Makita cordless Power drill: https://amzn.to/2KwRs0d

Makita cordless impact driver: https://amzn.to/2uVhhTC

Makita cordless Circular saw: https://amzn.to/2JzjZS7

Makita ROS: https://amzn.to/2rhP5q0

Makita track saw: https://amzn.to/2qkppHP

Festool kapex mitersaw: https://amzn.to/2HOctWo

4 Piece countersinks: https://amzn.to/2KB2HEy

12" Diablo combination table saw blade: https://amzn.to/2uZMRzR

Mirka Abranet sanding discs: https://amzn.to/2JyjS9F

Audio video equipment:

Video Camera: Panasonic HC-X920: https://amzn.to/2Kx6fb3

Soundcard: PreSonus AudioBox 22VSL: https://amzn.to/2I7qvlc

Bundle w/Audiobox 22VSL and Studio One software (DAW): https://amzn.to/2JPSDGH

Studio Mic: Marshall MXL 990: https://amzn.to/2jpB3OEh